For any construction project, the required quality of fabrication or Execution Class (EXC) must be stated. The system of determining the EXC has recently been amended. Now it must be determined according to the requirements of Annex C of BS EN 1993-1-1 and the National Annex associated with it. The Execution Class needs to be specified for:

- The works as a whole

- An individual component

- A detail of a component

The responsibility of the engineer is to specify the Execution Class for the structure (the works as a whole) and for details and components where it is required to specify an Execution Class different to that specified for the structure. Where different, the Execution Class for a detail or component must not be less than that specified for the works as a whole. The EXC for a detail or component should be distinctly identified in the execution specification if it is different to the EXC for the structure. The process to determine the Execution Class for buildings is an easy two-step process:

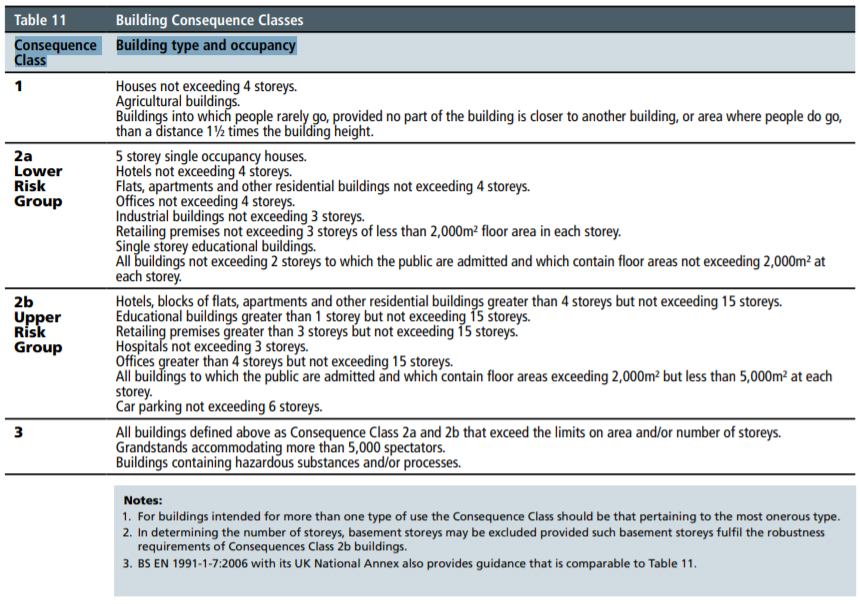

- Determine the Consequences Class: The reason for categorizing the Consequences Class (CC) is to make sure that the buildings are constructed with the appropriate level of quality control within the fabrication process. The CC for a building is derived on the basis of building height (number of storeys), building type, occupancy and floor plan area per storey (for retail). A structure, or a part of it, can also consist of components with different CCs. Table 11 of Approved Document A can be used to ascertain the Consequences Class for a range of building types & occupancy. In Table 11, CC2a and CC2b are subdivisions of CC2 when determining the Execution Class required for a structure.

- Select the Execution Class: Having determined the Consequences Class for a building, the relevant Execution Class is simply derived from Table NA.4 of the National Annex to BS EN 1993-1-1:2005+A1:2014. For the majority of buildings constructed in the UK, EXC2 will be the appropriate requirement. Where the Consequences Class is not specified, clause NA2.27.2 of the National Annex to BS EN 1993-1-1:2005+A1:2014 states that it should be considered that the design rules in BS EN 1993 are safe for Consequences Classes up to & including CC2. The engineer should always derive the EXC as per the design parameters appropriate to each project. The requirements to each Execution Class are listed in Table A3 of BS EN 1090-2 and can be reviewed by the engineer if needed. However, the engineer should refrain from over-specification of the Execution Class wherever possible to avoid extra costs. For example, EXC2 is the EXC derived for a project but the engineer requires full traceability i.e. an EXC3 requirement in place of the partial traceability requirement of EXC2. Instead of specifying EXC3 on the basis of achieving this single clause requirement, it is advised that EXC2 be still specified but along with the higher level of traceability added to the specification.

We at Eurotech provide CE Certification Services for construction products. With the help of our services, enterprises are able to produce more efficient, high performing and quality products in a fast, safe and uninterrupted manner. Many other certification services like CE Certification for medical devices, electrical/electronics, pressure equipment, RoHS etc. are also available.

For more information, contact trg@eurotechworld.net or fill out the form below to get your QUOTE today.